Table Water-curtain Spray Cabinet

- Category: Application of Film

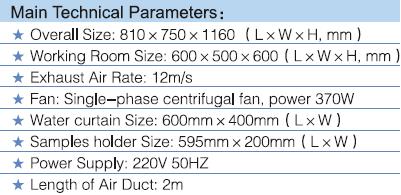

- Product description:Table Water-curtain Spray Cabinet

fan, so as to realize the cleansing of the spraying environment and the protection of people's health, as well as increasing the cleanliness of the works.

Structure Introductions

1.Coating mist collecting system: consists of stainless steel water-curtain plate, annular tank, water-curtain, and dash plate. Water-curtain plate, made of 1.5mm thickness stainless steel, facing towards operator. Water flows on its surface without break and pounding, maintaining a 2mm thickness water film. Most coating mist fully mixed with the water on the water curtain then flow into the annular tank, then filtered by the filter in the inlet of annual water pump.

2. Water supply system: consists of annual water pump, valve, overflow channel and pipes.3.Exhausting system: Consists of Baffle-type steam separator, centrifugal exhaust fan, several exhaust pipe and fan holder, belonging to large flow and low thickness exhaust. Steam separator with maze structure fixed behind the water-curtain plate, capable to efficiently separate and condense the mist in the air, then flow back to the annual tank in case over lost fluid.

CATEGORIES

- Whiteness Meter

- Paint,Coating&Ink

- Paper, Packaging & Print

- Paper Testing Machines

- Color Assessment Cabinet

- Temperature & Humidity Test Chamber

- Metal Testing Instrument

- Color and Gloss meter

- Particle Size and Shape Analyzer

- Coating Thickness Gauge

- Tensile Testing Machine

- Density Meter

- Color Fan Deck

- Textile Testing Equipment

- UV Visible Spectrophotometer

LATEST NEWS

Contact

CONTACT USName: Jennifer Zhang

Mobile:+86 13336040868

Tel:+86 13336040868

Whatsapp:+86 13336040868

Email:sales@iqctest.com

Add:No.51 of Xiba Road,Wuchang Street, Yuhang District, 311100 ,Hangzhou City, China