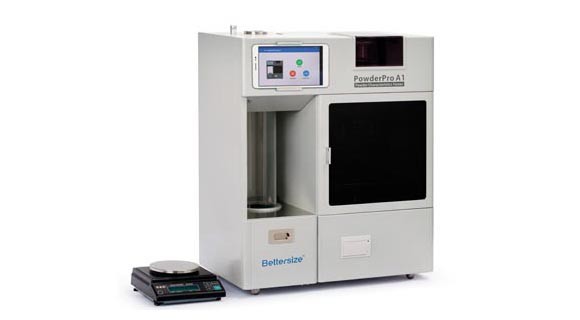

Bettersize Powder Physical Characteristics Tester

- Product Item : PowderPro A1

- Category: Particle Size and Shape Analyzer

- Powder Characteristics Analyzer

- Powder Physical Characteristics Tester

- Package : Wooden Box

- Product description:The PowderPro A1 integrates many state-of-the-art technologies such as intelligent control via Wi-Fi , image processing technology, and 3D electromagnetic vibration technology. It can measure the phys

The PowderPro A1 integrates many state-of-the-art technologies such as intelligent control via Wi-Fi , image processing technology, and 3D electromagnetic vibration technology. It can measure the physical properties of powders in a fast, simple, and accurate way. As an intelligent powder characteristics tester, it is an essential instrument to help you understand and research powder materials.

Features and Benefits

- ● Compact design

- ● Multiple controls

- ● Convenient data output

- ● Intelligent data transmission

- ● Automated control technology

- ● Automated imaging technology

-

Features and Benefits of PowderPro A1 Powder Physical Characteristics Tester

1. Measured and calculated parameters

PowderPro A1 measures fully automatic:

• Angle of Repose and Fall

• Angle of Spatula (Flat Plate Angle)

• Bulk and Tapped Densities

• Dispersibility

• Voidage and Cohesion

PowderPro A1 calculates fully automatic:

• Angle of Difference

• Compressibility

• Uniformity

Specification of PowderPro A1 Powder Physical Characteristics TesterMeasurement fully automaticParameters8 (measured) + 6 (calculated)Powdersmetallic and non-metallicConformity ISOISO 3953: 1993Conformity USPUSP32-NF27<616>Conformity EPEP7.0 07/2010: 20934ESieve size45 - 2000 µmAmplitude3 or 14 mmTapped frequency50-300 times per minute (continuous adjustment)Control terminalPC/Mobile (phone or pad)ConnectionWi-FiDimensions600 × 350 × 730 mm (L × W × H)Weight42 kgPower supplyAC 220 V, 50/60 Hz, 230 W

• Flowability Index

• Floodability Index

• Sieve Size

2. Measure angles with image method

Photographs were taken using high-definition CCD imaging technology. Parameters such as angle of repose, angle of fall and angle of spatula are obtained in a fast and easy way with high precision and good repeatability through the unique image recognition and processing technology.

3. Patented rotary vibration technology:

Ensure smooth surface of the powder and to improve measurement accuracy.

4. Automatic control technology:

Fully automatic PC or mobile control ensures easy usage and operation. Accurate and reliable test results are obtained by SOP mode for standardized testing process.

5. Conformity:

• ASTM D6393-08/D6393-14

• ISO 3953:1993

• USP32-NF27<616>

• EP7.0 07/2010:20934E

6. Data communication:

An electronic scale is connected to the instrument and the weight data is automatically transferred to the system for data processing and calculation of results.

7. Advanced technology of tapped density:

The tapped density is achieved through the perfect combination of variable frequency and rotary vibration technology. The vibration frequency of 50 to 300 times per minute can be continuously adjusted; vibration amplitude of 3 or 14 mm can be selected. During vibration, the cylinder is in a uniform rotation state, this guarantees the horizontal powder surface and improves the accuracy of the reading.

| Specification of PowderPro A1 Powder Physical Characteristics Tester | |

| Measurement | fully automatic |

| Parameters | 8 (measured) + 6 (calculated) |

| Powders | metallic and non-metallic |

| Conformity ISO | ISO 3953: 1993 |

| Conformity USP | USP32-NF27<616> |

| Conformity EP | EP7.0 07/2010: 20934E |

| Sieve size | 45 - 2000 µm |

| Amplitude | 3 or 14 mm |

| Tapped frequency | 50-300 times per minute (continuous adjustment) |

| Control terminal | PC/Mobile (phone or pad) |

| Connection | Wi-Fi |

| Dimensions | 600 × 350 × 730 mm (L × W × H) |

| Weight | 42 kg |

| Power supply | AC 220 V, 50/60 Hz, 230 W |

CATEGORIES

- Whiteness Meter

- Paint,Coating&Ink

- Paper, Packaging & Print

- Paper Testing Machines

- Color Assessment Cabinet

- Temperature & Humidity Test Chamber

- Metal Testing Instrument

- Color and Gloss meter

- Particle Size and Shape Analyzer

- Coating Thickness Gauge

- Tensile Testing Machine

- Density Meter

- Color Fan Deck

- Textile Testing Equipment

- UV Visible Spectrophotometer

LATEST NEWS

Contact

CONTACT USName: Jennifer Zhang

Mobile:+86 13336040868

Tel:+86 13336040868

Whatsapp:+86 13336040868

Email:sales@iqctest.com

Add:No.51 of Xiba Road,Wuchang Street, Yuhang District, 311100 ,Hangzhou City, China